MCP Mining Cable's Contribution to Mine Safety

MCP mining cables, with their excellent properties such as fire resistance, corrosion resistance, waterproofness, and resistance to mechanical damage, provide strong support for safe mine production. While ensuring stable power supply in mines, they also effectively enhance the mine's ability to respond to emergencies and reduce safety hazards caused by cable failures. With continuous technological advancements, their role in mine safety will become increasingly important. They are expected to be applied in a wider range of mining environments in the future, providing a more solid guarantee for safe, stable, and efficient mine production.

1. Fire Resistance Ensures Mine Fire Safety

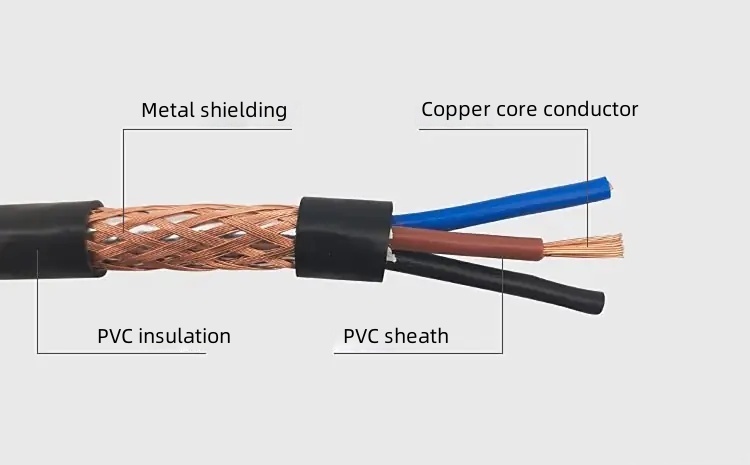

MCP mining cables utilize a high-quality fire-resistant outer sheath. This design effectively enhances the cable's ability to withstand high temperatures, preventing power outages or the spread of fires caused by cable overheating or fire. In deep working environments in mines, sudden incidents such as high temperatures and gas leaks are common, with fire being one of the most serious safety hazards. In a fire, conventional cables can burn through the insulation, causing short circuits and potentially even larger fires. Its fire resistance allows it to maintain power supply during a fire, ensuring the power system remains unaffected. It also reduces the spread of fire, buying miners valuable time to evacuate, effectively reducing the risk of mine fires.

2. Corrosion resistance enhances adaptability to mine environments

Mines, especially those in coal and metal mines, are often filled with harmful gases, moisture, and corrosive substances. Cables exposed to these harsh conditions for long periods of time are susceptible to corrosion, which can impact the stable supply of power. The cable's outer sheath is constructed of a special corrosion-resistant material that effectively resists the chemicals and moisture present in mines. This corrosion resistance significantly extends the cable's service life, reduces power failures caused by cable aging and corrosion, and ensures the long-term stable operation of the mine's power system, safeguarding safe production.

3. Waterproof and moisture-resistant, ensuring power system stability

The humid environment within mines is a major hidden danger for power systems. Cables exposed to prolonged humid conditions are highly susceptible to electrical short circuits or leakage, even leading to electric shock accidents. Its excellent waterproof properties effectively block moisture penetration, preventing electrical failures within the cable. Deep underground, moisture and humidity are particularly severe. Its waterproof design effectively ensures the safety and stability of the power supply system. Even in the presence of water accumulation or strong currents in mines, MCP mining cables can maintain the normal operation of the power system, providing a strong guarantee for safe mine production.

4. Mechanical Damage Resistance, Enhanced Cable Durability

Cables in mines are often exposed to physical impact and mechanical damage from mining vehicles, equipment, tools, and miners' operations. Traditional cables can break or break after certain impacts, causing power outages or electrical failures. This cable features a reinforced mechanical protection layer that effectively withstands external mechanical pressure and impact. It maintains excellent integrity against vibrations generated during equipment handling and mine transportation, as well as impacts during underground operations, significantly reducing the risk of power system failures caused by cable damage.

5. Low Smoke and Halogen-Free, Protecting Miners' Health

The air in mines is sealed. In the event of a fire, smoke can spread rapidly, posing a serious threat to miners. It utilizes environmentally friendly, low-smoke, halogen-free materials, producing minimal smoke and no toxic gases during combustion. This design not only reduces the risk of toxic gases from fires to miners but also effectively increases the chances of escape for those inside the mine. In the event of a cable failure or short circuit, its low-smoke, halogen-free properties ensure air quality within the mine, reducing the risk of suffocation caused by smoke, and creating a safer working environment for mine production.

6. Ensuring the Reliability and Continuity of the Power System

MCP mining cables play a vital role in ensuring a long-term, stable power supply. As crucial power transmission equipment in mines, they must not only carry high loads but also operate stably in complex environments. They are capable of providing power to various equipment in mines for extended periods under harsh operating conditions, ensuring uninterrupted production processes. Their excellent electrical performance and stability make them a vital component of mine power systems, providing a solid foundation for mine safety and production efficiency.

TAG:

Previous

Next

Previous:

Next: