The Ins and Outs of Welding Cable Size: A Guide for DIY Enthusiasts

Understanding Welding Cable Size

When it comes to welding, picking the right equipment is crucial. One element that often gets overlooked is the welding cable size. Not only does it impact your welding performance, but it also plays a significant role in safety. So, let's dive into the nitty-gritty!

Why Does Cable Size Matter?

Imagine you're gearing up for a project, and you've got your helmet on, your gloves ready, and then... you realize your cable isn't up to snuff! Ugh, right? The welding cable size determines how much current can flow through it without overheating. A cable that's too small? Well, it might not just ruin your project; it could also pose a fire hazard. Yikes!

Ampacity: The Key to Choosing the Right Size

Now, here's the kicker! The term you'll want to get cozy with is ampacity, which refers to the maximum amount of electrical current a conductor or device can carry before sustaining immediate or progressive deterioration. The thicker the cable, the more amps it can carry. So, if you're planning on welding with high amperage—think 200 amps or more—you'd better opt for a thicker cable.

A Quick Guide: Common Cable Sizes

Alright, let's get down to brass tacks! Here's a quick rundown of common welding cable sizes:

- 6 AWG: Suitable for small projects or machines under 100 amps.

- 4 AWG: Good for medium projects, typically for 100-150 amps.

- 2 AWG: Ideal for larger machines, handling 150-200 amps.

- 1 AWG: Best for heavy-duty welding, usually exceeding 200 amps.

Length Matters!

But wait, there's more! Not only does the size of the cable matter, but the length does too. The longer the cable, the more voltage drop you'll experience, which can impact your weld quality. A good rule of thumb? Keep it short and sweet if you can!

Safety First: Checking Your Equipment

Don't just take the manufacturer's word for it; do your own checks! Look for any signs of wear and tear. Frayed cables? That's a no-go. You need to ensure that your equipment is in tip-top shape before you start your welding journey. Safety first, folks!

Additional Considerations

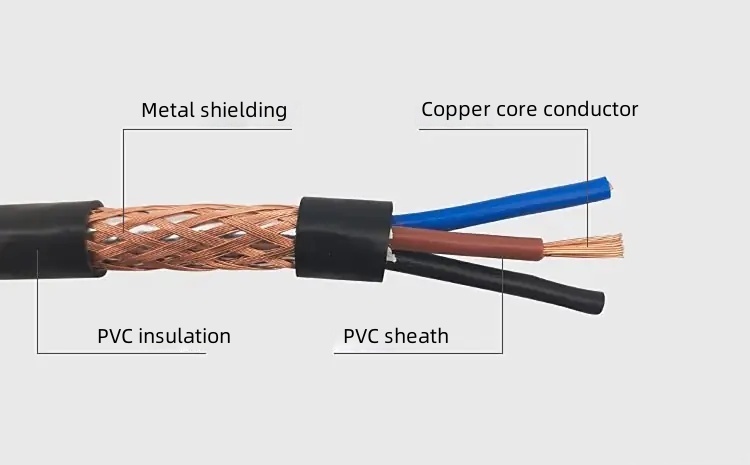

When you're knee-deep in cables, don't forget about insulation. The type of insulation can also influence the overall performance of your welding cable. Look for cables with high-quality rubber or thermoplastic insulation. They'll stand up against heat and abrasion, making them perfect for tough jobs.

Conclusion: Get It Right!

In summary, folks, when it comes to welding cable size, knowledge is power. Make sure to choose a cable that fits your project's amperage and length requirements. It might seem like a small detail, but trust us, it can make a world of difference in your welding endeavors. So, gear up, choose wisely, and let your welding skills shine!

TAG: